Cocoa is the

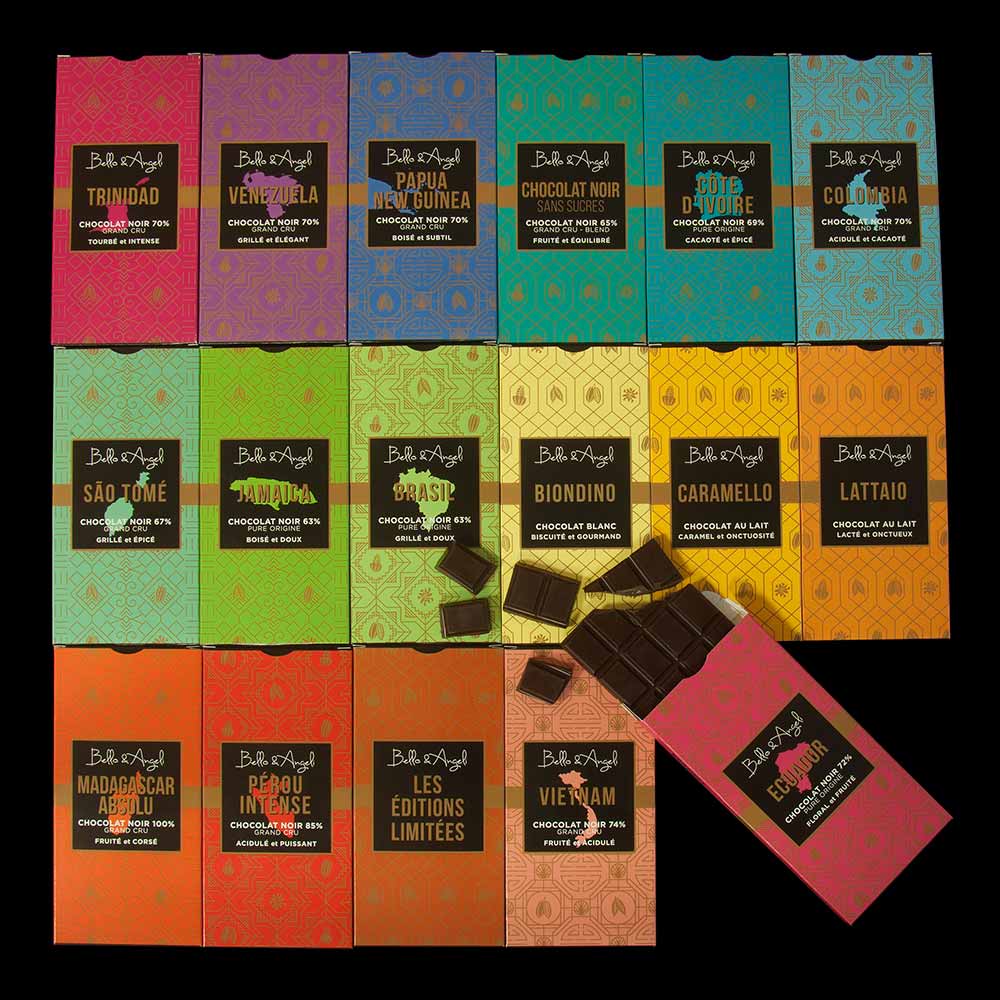

When making chocolate, the choice of cocoa is crucial because there are as many types of cocoa as there are regions. Because of its terroir and variety, a cocoa will develop different aromatic notes and this will make it unique. Then, the know-how of transforming the cocoa into chocolate will give all its magic to this exceptional product.

We will therefore take you on a journey from cocoa to chocolate to show you the main stages that enable us to select and offer you exceptional chocolates.

Cocoa is grown in the equatorial belt. It originated in the Americas and was later introduced to West Africa and Asia.

Although there are many varieties of cocoa trees, they can be broadly classified into three main varieties: criollo, forastero and trinitario. This classification is somewhat stereotypical, although it is very common, because over time the varieties have crossed to give rise to hybrids or specific local evolutions. This sometimes makes it difficult for farmers to specify the variety on their farms.

The terroir and the type of plant have given the cocoa its initial nature and its basic characteristics, this raw beauty will then be shaped by the hand of Man.

Once harvested, the cocoa pod is opened ("shelling") and its contents, consisting of seeds mixed

Once the fermentation process is complete, the cocoa beans are browned and dried. They are then placed in the sun to complete the drying process.

At the end of the drying process, the seeds are sorted to eliminate the rejects (badly formed seeds, etc.). What is known as "merchant cocoa" has just come into being. The production of cocoa products and chocolate can then begin.

The first product made from cocoa is cocoa powder. By pressing cocoa beans with a high-pressure press, cocoa cake and cocoa butter are obtained. The cake, when crumbled and ground, will become cocoa powder.

Merchantable cocoa can also be used in the manufacture of chocolate.

In this case, it is roasted and then

The liquid obtained is then poured into moulds and, as it cools, will form blocks of chocolate.

As you will have understood, the chocolate obtained during this transformation depends on the quality and nature of the raw materials, particularly the cocoa used, but also on the know-how during the transformation of the bean (roasting, grinding, conching, etc.). This transformation is the domain of the"couverturier".

The product resulting from this process provides an extremely varied and interestingstarting point for the chocolatier to express his creativity.

We would like to thank Arnaud and Franck in particular, with whom we have been working for many years. They are passionate, authentic and welcoming, and thanks to them, we benefit from exceptional chocolates that we use in our recipes.